+8613256742787

Станок для лазерной резки металла, Станок для лазерной резки волокна, Поставщик станков для лазерной резки, Лазерная маркировочная машина, Волоконный лазерный маркировщик...

+8613256742787

Станок для лазерной резки металла, Станок для лазерной резки волокна, Поставщик станков для лазерной резки, Лазерная маркировочная машина, Волоконный лазерный маркировщик...

Новости компании

Дом >> Блог >> Новости компании

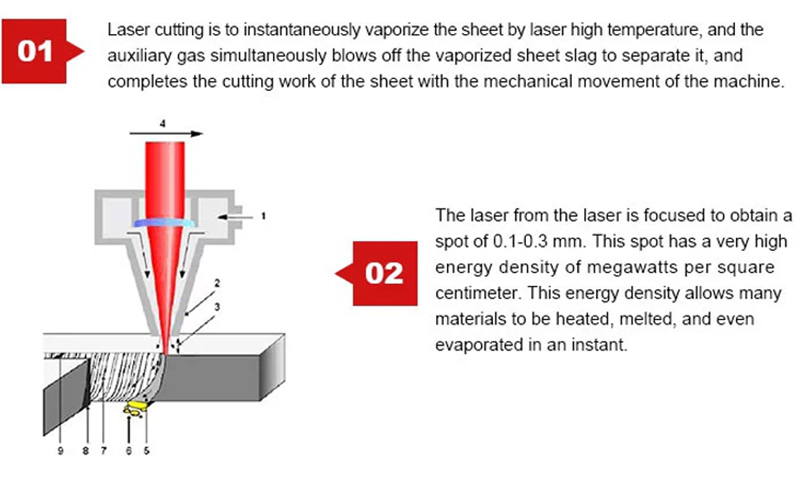

With the development of laser technology, the laser cutting machine has broken the traditional processing method, and the new production process has been widely used in various industries. The optical fiber cutting machine has developed explosively. People are paying more and more attention to the perfect cutting effect. The auxiliary gas plays a very important role in the cutting process. This is also a key link for perfect cutting. Here is a brief introduction why the auxiliary gas should be added during the cutting process and how to use it properly.

1. Why add auxiliary gas to laser cutting machine?

The function of the auxiliary gas: 1. blow away the slag in the kerf, 2. cool the surface of the processed object, reduce the heat affected zone. 3. Cool the focusing lens to prevent the dust from entering the cutting head and contaminating the lens and causing the lens to overheat.

The choice of gas pressure setting and type has a large influence on the cutting effect, so it is necessary to select a suitable gas and adjust the pressure.

2. How to choose the auxiliary gas of laser cutting machine ?

The auxiliary gases that can be used in laser cutting machines are mainly oxygen, nitrogen, air and argon. How to match the gas as follows

1), air

Air can be supplied directly from the air compressor, so it is very cheap compared to other gases. Although the air contains about 20% oxygen, the cutting efficiency is far less than that of oxygen, and the cutting ability is similar to that of nitrogen. A slight amount of oxide film on the cut surface will appear yellow at the end of the cut.

The main materials are aluminum, aluminum alloy, stainless copper, brass, plated steel, etc.

2), nitrogen

Some metals use oxygen to form an oxide film on the cutting surface during cutting, and nitrogen can be used to prevent oxidation-free cutting of the oxide film. The end face of the slit is whitish.

The main applicable plates are stainless steel, plated steel, brass, aluminum, aluminum alloy, etc.

3), oxygen

Mainly used in laser cutting machine to cut carbon steel. While the oxygen reaction heat is used to increase the cutting efficiency, the resulting oxide film increases the beam spectral absorption factor of the reflective material. The end of the slit is black or dark yellow. Mainly suitable for carbon steel

4), Argon

Argon is an inert gas used to prevent oxidation and Nitriding in laser cutting machine cutting. It is also used in welding. Compared with other processing gases, it is expensive and increases the cost accordingly. The end face of the slit is whitish.

The main materials are titanium, titanium alloy, etc.

Анализ факторов, влияющих на качество лазерной резки, и способы его контроля

Как обслуживать станок для лазерной резки с волоконным лазером

+8613256742787

Адрес: комната 2309, строение 3, квартал Львди Жуйли, район Шичжун, город Цзинань, провинция Шаньдун, Китай.