+8613256742787

Станок для лазерной резки металла, Станок для лазерной резки волокна, Поставщик станков для лазерной резки, Лазерная маркировочная машина, Волоконный лазерный маркировщик...

+8613256742787

Станок для лазерной резки металла, Станок для лазерной резки волокна, Поставщик станков для лазерной резки, Лазерная маркировочная машина, Волоконный лазерный маркировщик...

Новости технологий

Дом >> Блог >> Новости технологий

Bicycles bring great convenience to people's travel, and successfully solve the problem of short-distance travel. Promote the development of the entire bicycle industry. I don't know if you have noticed that the bicycles on the market are engraved in a row. Most of them are copied and produced in batches on the production line.

In this high-tech era, professional laser cutting machines can help you create a bike that is unique to you.

Tube laser cutting machines have developed very well in recent years. At present, bicycle skeletons are made of pipes. The use of pipes as bicycle skeletons has the following two advantages. First, the weight is relatively light, and second, the pipes have a certain strength. Most of the pipe materials used for bicycles are aluminum alloy, titanium alloy, chromium-molybdenum steel, and carbon fiber, which enhances the design capacity of pipes and structures and innovates processing technology, becoming the eternal melody of innovation and development in the bicycle industry.

Tube Laser Cutting Machine is a special machine tool that uses laser technology to perform various graphic cutting on pipe fittings and profiles. It is a high-tech product that combines CNC technology, laser cutting, and precision machinery. It has the characteristics of professionalism, high speed, high precision, high efficiency, high-cost performance, etc. It is the first choice for the non-contact metal pipe processing industry.

Compared with the traditional cutting process, the laser cutting machine has a smoother cutting section of the pipe processed by the laser cutting machine, and the cut pipe can be directly used for welding, reducing the processing steps of the bicycle industry. Compared with traditional pipe processing, which requires cutting, punching, and bending, the traditional pipe processing technology consumes a lot of molds. Laser cutting pipe not only has fewer procedures, high efficiency, but also the quality of the cut workpiece.

Therefore, the bicycle built by the laser cutting machine is not only beautiful in appearance and personality but also can beat those ordinary bicycles in performance. It is a good way to produce and process small batches of bicycles.

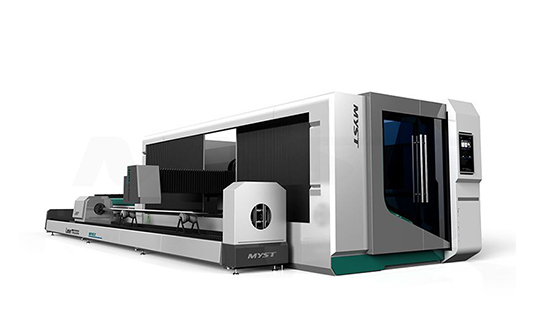

The tube laser cutting machine produced by JINAN MYST Laser Equipment company can professionally cut and process various square tubes, round tubes, and other shapes of tubes, and cut any design graphics on the tubes. Fast speed, high precision, one-time forming, no need for subsequent processing. No need for casting mold, cost-saving, visual layout, close-fitting, and material saving.

Анализ факторов, влияющих на качество лазерной резки, и способы его контроля

Как обслуживать станок для лазерной резки с волоконным лазером

+8613256742787

Адрес: комната 2309, строение 3, квартал Львди Жуйли, район Шичжун, город Цзинань, провинция Шаньдун, Китай.