+8613256742787

Станок для лазерной резки металла, Станок для лазерной резки волокна, Поставщик станков для лазерной резки, Лазерная маркировочная машина, Волоконный лазерный маркировщик...

Новости технологий

Дом >> Блог >> Новости технологий

In recent years, laser cutting CNC machines have become the most popular metal processing equipment on the market. Compared with previous gas laser machines, metal cutting machines have significant cutting advantages and have become the first choice in the field of high-precision laser processing. The metal laser cutter can be used for cutting metal plates, whether it is right-angle cutting or bevel cutting, it can ensure that the cutting edge is smooth and flat without burrs, and it is tender enough to meet customers' higher-precision cutting requirements. And the laser cutting machine has absolute advantages in work efficiency, consumables, and environmental protection, and it is a well-deserved high-tech product. How do we extend the service life of laser cutter metal in our daily use process? MYST Laser will give the answer from the following three aspects.

Laser cutting head

Precautions for the correct operation of the laser cutting machine metal sheet:

In the daily processing process, if you want to extend the service life of the laser cutter machine, you first need to master the correct operation of the laser cut metal machine. When the metal cutting with a laser machine is working, if there is a failure, it will not only delay the work efficiency but also have potential dangers. Novices must be trained by professionals before they can work independently.

1.Before using the machine, the operator must undergo professional training to understand the fiber laser cutting machine working principle, structure, and performance of the fiber laser cutting machine, and master the relevant professional knowledge of the fiber laser cutting machine operating system.

2.Follow the operation procedure of the metal cutting by laser machine and start the machine in strict accordance with the instructions.

3.It is necessary to clarify whether the material can be used for laser cutting or heating before processing, so as to avoid material damage and toxic gas generation during processing.

4.Operators should be equipped with protective equipment according to the regulations, and professional protective glasses should be worn when contacting the laser beam at a close distance.

Equip with protective equipment

5.During the working process of the metal cutter laser, the operator shall not leave or take care of it without permission. If you need to leave in an emergency, you need to turn off the machine or disconnect the power supply.

6.When using gas tanks, pay attention to the position of the welding wire to avoid gas leakage caused by crushing. The transportation and use of gas tanks must comply with gas tank supervision regulations. The gas tank will explode when heated, so it is forbidden to place it in the sun or near a heat source. When opening the tank valve, the staff should stand by the mouth of the tank.

7.After inputting the new part program, you should test run the laser cutter for metal first and check whether the machine can operate normally.

8.The generator, bed, and surrounding areas of the CNC laser cutter should be kept clean and orderly, and the workpieces, plates, and waste materials should be placed in an orderly manner.

Fiber laser cutting machine

9.A fire extinguisher should be placed in the working area of the metal cutter machine, and the operator is familiar with the location of the fire extinguisher. Turn off the stopper immediately after processing. Avoid placing flammable materials such as paper chips and wood chips in the working area of the machine.

10.When an abnormality occurs during the processing of the steel cutting machine, it is necessary to immediately shut down the shutdown device, repair the fault in time and report it to the management personnel.

Daily maintenance of laser metal cutting machine:

In the daily production process, if you want to extend the service life of the laser cutting machine for metal and maintain the machine's long-term and efficient work, maintenance is essential on the premise of operating the steel cutter machine correctly.

Daily maintenance of metal laser cutting machine

Each time you start the metal laser cut machine, you need to check whether the position of the cutting head is appropriate to ensure that the starting point of the cutting head and the distance from the table surface are correct during the working process to avoid collisions between the cutting head and the processing material during the processing.

Laser cutting head

2.Before operating the laser machine for metal cutting, it is necessary to check whether the amount of auxiliary gas in the gas cylinder is sufficient; if the air is used as the auxiliary gas, it is necessary to check whether the pressure of the air compressor is sufficient.

3.Staff need to check whether the water and water temperature of the chiller meet the set requirements of the laser machine metal cutting, to ensure that the water is sufficient, to avoid damage caused by insufficient cooling water that can not cool the cutting head in time.

4.Check the metal laser cutting machine gas circuit, water circuit, oil circuit, the joints and pipelines of the pneumatic components for leakage, and whether the parts are in good condition.

5.At the end of the work, do a good job of cleaning the laser cutting metal machine, do not place debris on the body, and ensure that the parts of the machine are tidy.

6.At the end of the work, discharge the wastewater from the air compressor in time. Open the drain valve of the air storage cylinder at the bottom of the air compressor and close it when the wastewater is exhausted.

Air compressor for fiber laser cutting machine

7.After finishing the day’s work tasks, turn off the metal cutter laser machine according to the shutdown steps specified in the instructions. Finally, disconnect the main power supply of the machine.

Regular maintenance of the laser-cut metal machine

If you want a long service life of the laser cutter machine metal, you also need to conduct regular maintenance, conduct a comprehensive inspection once a week, or make an inspection plan based on the frequency of use of the machine.

1.The loss of the cutting nozzle of the cutting head needs to be checked regularly, and it needs to be replaced in time when the loss is serious.

2.Regularly check the sharpness of the lens inside the cutting head and clean it appropriately.

3.Each pipe of the aluminum cutting machine needs to be kept unobstructed to ensure that there is no impurity or blockage.

4.Check whether the fixing screws of each part of the laser cutter CNC machine are loose

5.The straightness and verticality of the guide rail should be checked regularly, and timely debugging should be carried out in case of deviation. The guide rails and racks of the CNC laser cutting machine should also be cleaned regularly, and lubricants should be applied frequently to ensure that there is no debris.

Measuring precision of guide rail

How to solve the problems of the steel laser cutter machines during processing?

Laser cutting for steel machine is a commonly used metal processing equipment on the market, and some problems will inevitably occur during use. In order to minimize losses, how do we solve problems when they arise?

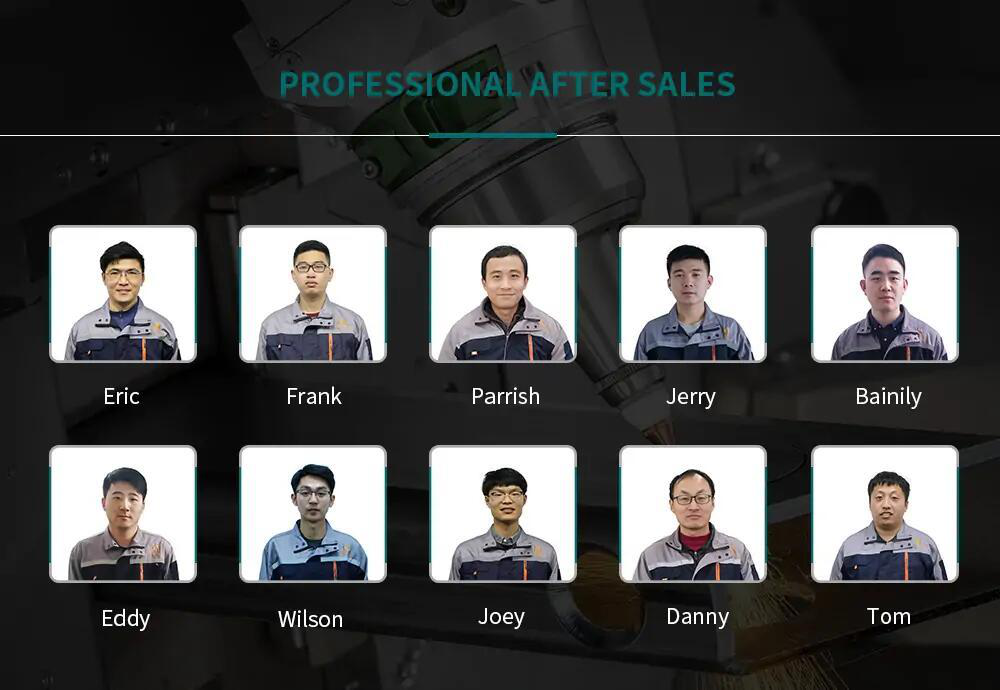

If you have experience in using fiber laser cutting machinery, you can determine the problem and solve the problem yourself. However, most steel cutting laser machine users are using the machine for the first time and have not had any contact before. In this case, contact the after-sales team of the CNC metal cutting machine manufacturer and let professional after-sales personnel solve the problem. It should be noted that some small steel laser cutting machine manufacturers do not have their own after-sales team, so the problems that arise cannot be solved in time. MYST Laser has its own professional after-sales team, and customers' after-sales problems can be solved in a timely and effective manner.

MYST after-sales team

1.MYST Laser has 120 after-sales service personnel, including 10 professional after-sales engineers, who provide professional technical support.

2.After-sales personnel communicates with each other in Britain without any barriers, and foreign customers do not need to worry about communication problems.

3.All after-sales personnel have undergone professional pre-job training, and the service quality is guaranteed.

4.24-hour manual online, solve customer problems timely and efficiently in the shortest time.

5.MYST Laser sells five different types of laser processing equipment: fiber laser cutter machine, laser welding machine, laser cleaning machine, laser marking machine, and plasma cutting machine. The after-sales service of different types of models is separated separately. The company is divided into groups according to the machine types that the after-sales personnel is good at, and the service is more professional. The following is the contact information of the MYST laser after-sales team leader:

Main Laser Equipment

1.Tom is mainly responsible for the fiber laser cutting machine, laser welding machine, laser cleaning machine

Email: Aftersale01@lxshow.net

Whatsapp/Wechat +8615106988612

2.Joey is mainly responsible for the laser marking machine

Email: Service01@lxshow.net

Whatsapp/Wechat:+86 150 9894 3713

3.Wilson is mainly responsible for the plasma cutting machine

Email: Aftersale02@lxshow.net

Whatsapp/Wechat:+8615610124201

4.Kevin is mainly responsible for the laser cutting machine and laser marking machine

Email:Aftersale03@lxshow.net

Whatsapp/Wechat:+8615621881002

The use of laser fiber cutting machine in daily life is becoming wider and wider. More people are starting to use laser cut machine. After carefully reading this article shared by MYST Laser, you can easily grasp the secrets of extending the service life of laser cutting machine fiber in daily use.