+8613256742787

Станок для лазерной резки металла, Станок для лазерной резки волокна, Поставщик станков для лазерной резки, Лазерная маркировочная машина, Волоконный лазерный маркировщик...

+8613256742787

Станок для лазерной резки металла, Станок для лазерной резки волокна, Поставщик станков для лазерной резки, Лазерная маркировочная машина, Волоконный лазерный маркировщик...

Новости технологий

Дом >> Блог >> Новости технологий

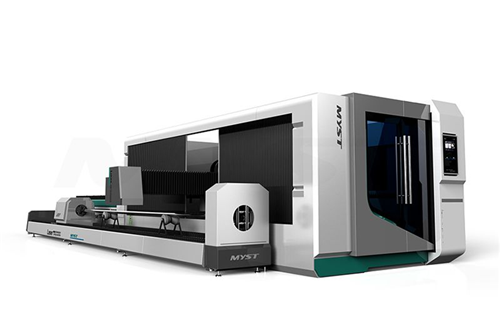

The market for CNC metal laser cutter is getting bigger and bigger, and more and more people are beginning to notice it. Some time ago, some of the sheet metal laser cutters of MYST Laser were promoted. Many customers asked how to choose the power of the laser cutting machine steel plate when purchasing. today MYST Laser shares how to choose the power of the laser metal cutting machine.

Metal laser cutting near me has a wide range of applications, including metal processing, sheet metal processing, medical equipment, elevator manufacturing, and many other industries. Before determining the power of purchase, it is necessary to determine the material used for processing and the cutting thickness range in order to determine the machine Processing format and model to facilitate later purchases.

According to the processing material and material thickness, after the machine model is determined, the metal laser cutter for sale manufacturer can recommend the appropriate machine power. The 1000w laser cutting machine is suitable for cutting metal sheets below 6mm. If the production volume is large, or processing The thickness of the material is large, and a higher power fiber laser cutting machine can be selected as appropriate. Generally, small and medium power fiber laser cutting machines below 4000W can meet the needs of most users. Fiber laser cutting machines with different powers have different cutting capabilities. Quality and cutting speed have a decisive influence. The higher the power, the greater the thickness of the metal sheet that can be cut. Customers with larger cutting thickness requirements can choose fiber laser cutting machine 6000W, 8000w fiber laser cutter.

The fiber laser cutting machine raycus has outstanding advantages in sheet metal processing. It relies on the high temperature generated by the laser, melts and irradiates the surface of the sheet metal, and controls the displacement through numerical control to achieve the purpose of cutting. The advantages of laser processing are mainly reflected in the fact that there is no deformation, high flexibility, small slitting, smooth section without burrs, and it can cut arbitrarily complex graphics workpieces. Customers with sheet metal processing needs can consult on the MYST official website for power selection and other issues. We have a professional sales manager to help you answer questions.

For the choice of metal laser cutting machine power, the material to be cut and the cutting thickness are two necessary factors that need to be considered. When choosing a fiber laser cutting machine, you must first explain these two points to the manufacturer. MYST Laser hopes that everyone can buy a fiber laser cutting machine that meets their own production needs.

Анализ факторов, влияющих на качество лазерной резки, и способы его контроля

Как обслуживать станок для лазерной резки с волоконным лазером

+8613256742787

Адрес: комната 2309, строение 3, квартал Львди Жуйли, район Шичжун, город Цзинань, провинция Шаньдун, Китай.